Primers | EPGUARD 1600

Fast Dry / High Build | Epoxy Primer

Product features

- Excellent adhesion, hardness and abrasion resistance

- High build capabilities

- Low V.O.C.

- Easy to apply with any traditional painting equipment

- Excellent intercoat adhesion with subsequent coatings

- Very good recoatability (up to 30 days)

- For increased performance and protection topcoat with Glass Shield polyurethanes.

Find a local retailer »

Suggested Use

Steel structures or equipment (various types)

Aluminum (vinyl wash primer or AGA 2000 required)

Wood

Fiberglass

Concrete

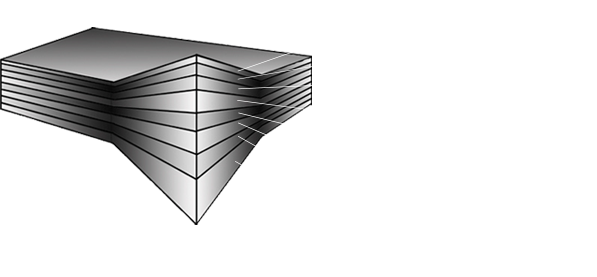

Typical Sequence (First class finish)

In doubt? Contact technical services at 1-800-361-6652 for proper guidance in preparing substrate

Mixing and Thinning

EP-GUARD™ 1600, is a two component product supplied in a 5 US gallons or 1 US gallon containers which contain the proper ratio of ingredients. The entire contents of each container must be mixed together. Power mix the base portion first to obtain a smooth, homogeneous product.

After mixing the base portion for 5 to 10 minutes, add component “B” (clear catalyst GS 161-49C) slowly with continued agitation. After the component B add is complete, continue to mix slowly until homogeneous. Allow a 20 minutes induction time before using.

Thinning is not normally required or desired; however, at lower temperatures, small amounts (10% or less) of Glass Shield GS 162-11S thinner can be added depending on local VOC and air quality regulations. Any solvent addition should be made after the induction time.

The pot life of the mixed material is 8 hours at 77ºF (25ºC). Higher temperatures will reduce the pot life of the product; lower temperatures will increase it.

Application Conditions

Industry standards are for the substrate temperatures to be above 10º C of the dew point. Condensation due to substrate temperatures below the dew point can cause flash rusting on prepared steel and interfere with proper adhesion to the substrate.

Special application techniques may be required above or below normal application conditions.

| Condition | Material | Surface | Ambient | Humidity |

| Normal | 60 - 85ºF (16 - 29ºC) |

60 - 85ºF (16 - 29ºC) |

60 - 90ºF (16 - 32ºC) |

0 - 65% |

| Minimum | 50ºF (10ºC) | 50ºF (10ºC) | 50ºF (10ºC) | 0% |

| Maximum | 90ºF (32ºC) | 100ºF (35.5ºC) | 100ºF (35.5ºC) | 85% |

Application

EP-GUARD™ 1600 can be applied by brush, roller or spray methods. The preferred method of application is with heavy duty airless spray. De Vilbiss or equivalent equipment should be used.

For HVLP applications, please consult and follow with equipment supplier’s instructions

Air spray should be: MBC-510 or JGA gun, 704 or 765 air cap and “E” or “EX” tip and needle. For airless application a tip with 0.013” (0.330 mm) to 0.017” (0.431 mm) orifice, 1,500 psi constant pressure at tip.

Surface Preparation

All coatings systems provide the maximum performance over adequately prepared surfaces. There are, however, structures where it is not possible to obtain an ideal surface condition. The surface preparation recommended for EP-GUARD™ 1600 series is to include removal of all oil, grease, dirt, dust, mill scale, rust, paint, oxide, corrosion product and other foreign matters. This can be accomplished with hydroblasting, grit sweeping and with a variety of mechanical descaling tools. The minimum standard for steel is Steel Structures Painting Council Standard SSPC-SP-2 or SSPCSP- 3. The recommended surface preparation is SSPC-SP-6. For aluminum, proper etching of substrate and application of a vinyl wash primer is required before applying EP-GUARD™ 1600.

Technical Data

| Coating type | Polyamide epoxy - Two component |

| Colour | White (1653) / Grey (1652) / Black (1659) Other colors available upon request |

| Packaging | 3.78 L (1 US Gallon) 15.12 L (4 US Gallon) |

| Mixing Ratio | 4 : 1 per volume |

| Gloss | Semi gloss |

| Flashpoint | -4º C (25º F) |

| Induction time | 20 minutes |

| Thinner | GS 162-11S |

| Pot life | 8 hours |

| Temperature resistance | 100º C (212º F) in service |

| Solids (ASTM D1644) | |

| By weight | 6 +/- 2% (depending on colour) |

| By volume | 64 +/- 2% (depending on colour) |

| Theoretical spreading rate | 24 sq.m / lat 25 microns dry |

| Theoretical spreading rate | 1021 sq.ft. / US gal at 1 mil |

| Recommended film thickness | 75-100 microns dry (3.0 - 4.0 dry mils)(min. 1.5, max. 5.0 mils) |

| Application methods | Spray, brush or roller |

Airless & Air Spray

| Manufacturer | Graco |

| Pump | 30 : 1 |

| Fluid hose | 3/8” x 100’ max |

| Tip size | 311, 413, 515, 517 |

| PSI | 3500 PSI min. |

| Manufacturer | Devilbiss | SATA |

| Spray gun | HET | K3 RP |

| Fluid tip | 1.1 ff | 1.1 |

| Air cap | #410 / 414 | |

| Fluid line | 3/8” | 3/8” |

| Pressure pot | 15 - 25 psi | 40 psi |

| Atomizing air | 50 - 60 psi | 36 psi |

Curing Schedule

These times are based on a 2.0-3.0 mil (50-75 micron) dry film thickness. Higher film thickness, insufficient ventilation or cooler temperatures will require longer cure times and could result in solvent entrapment and premature failure of the film. Maximum recoat time is 30 days without special surface preparation. Consult technical services for recommendations and test results. If the maximum recoat time has been exceeded, the surface must be sanded or prepared with a brush off blast SSPC-SP-7 prior to the application of additional coats. EP-GUARD™ 1600 applied below 40ºF (4ºC) may temporarily soften for several hours, after temperatures rise to 60ºF (16ºC). This is a normal condition and will not influence performance.

| Catalyst | 161-49C |

| Dry to touch | 1 hour |

| To recoat | 60 to 90 minutes (max 30 days) |

| Hard | 12 hours |

| Full cure | 7 days |

DISCLAIMER: All information is given in good faith. Since conditions of use are beyond the manufacturer’s controls, all information contained herein is without warranty, implied or otherwise. All technical data and specifications are subject to change. Please consult with your Glass Shield representative for more detailed coating recommendations. Revised 04-01-2007