our solutions by industry | water treatment facility

Potable Water Tanks | Exterior

1. Sandblast to obtain a surface profile of 1 to 1.5 mils complying with the standard SSPC-SP6 (commercial blast).

2. Apply two coats of anti-corrosion primer MC-4390 to obtain a minimal dry film thickness of 8 mils.

3. Topcoat with Glass-Guard polyurethane 2800 Series to obtain a dry film thickness of 3 mils.

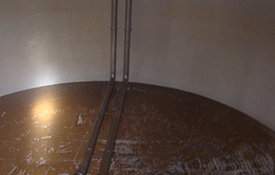

Potable Water Tanks | Interior

1.Sandblast to obtain a surface profile of 1 to 1.5 mils complying with the standard SSPC-SP5 (white metal blast).

2. Apply one coat of EP-Guard white epoxy primer 1553 to obtain a dry film thickness of 3 mils.

3. Topcoat with EP-Guard grey epoxy primer 1552 to obtain a dry film thickness of 3 mils.

Water Treatment Facility

1. Brush with a steel brush or an electrical device to obtain a surface complying with the standard SSPC-SP2 (hand tool cleaning).

2. Treat surface with GS-202 rust converter and let product stand for 24 hours. Wipe or brush residues.

3. Apply with a natural bristle brush two generous coats of anti-corrosion primer MC-4390 in order to obtain a dry film thickness of 4 to 6 mils. Let dry for 5 hours.

4. Topcoat with Glass-Guard polyurethane 2800 Series to obtain a dry film thickness of 3 mils.